Screw Air Compressors for Industrial Applications

Efficient, Durable, and Customizable Solutions from IVITAL

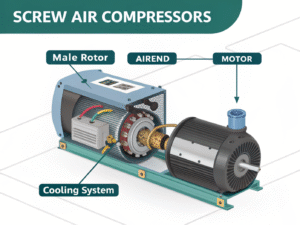

Understanding Screw Air Compressors

What is a Screw Air Compressor?

A screw air compressor is a type of positive displacement compressor that uses two intermeshing helical screws to compress air. These compressors are known for their reliability, energy efficiency, and continuous duty operation capabilities, making them ideal for industrial applications requiring consistent compressed air supply.

Working Principle

Screw compressors operate by trapping air between two counter-rotating screws. As the screws rotate, the volume between them and the housing decreases, compressing the trapped air. The compressed air is then discharged through an outlet port. This continuous rotary motion provides smooth, pulse-free air delivery with minimal vibration and noise compared to reciprocating compressors.

Industry Applications

Screw Air Compressor Advantages

Discover why screw air compressors are the preferred choice for industrial applications requiring reliable and efficient compressed air solutions.

Energy Efficient

Optimized compression technology reduces energy consumption by up to 30% compared to conventional compressors, resulting in significant cost savings over time.

Stable Air Supply

Continuous rotary motion ensures consistent air pressure and flow rate, eliminating pulsation issues common in reciprocating compressors for reliable operation of pneumatic equipment.

Low Noise & Vibration

Advanced engineering reduces operational noise to as low as 65dB, creating a more comfortable working environment while minimizing structural vibration and associated maintenance issues.

Continuous Operation

Designed for 24/7 operation with 100% duty cycle capability, screw compressors excel in demanding industrial environments requiring uninterrupted compressed air supply.

Screw vs. Reciprocating Compressors

| Feature | Screw Compressors | Reciprocating Compressors |

|---|---|---|

| Energy Efficiency | High - Variable speed options available | Medium to Low - Fixed speed operation |

| Noise Level | Low (65-75 dB) | High (80-95 dB) |

| Duty Cycle | 100% - Continuous operation | 50-70% - Requires cooling periods |

| Maintenance | Low - Fewer moving parts | High - More wear components |

| Air Quality | Higher - Less oil carryover | Lower - More contamination risk |

| Vibration | Minimal - Smooth operation | Significant - Requires isolation |

Product Categories

Explore our comprehensive range of air compressor solutions designed for various industrial applications.

Oil-lubricated Screw Air Compressors

Our oil-lubricated screw air compressors deliver exceptional performance and reliability for demanding industrial environments. These units offer optimal energy efficiency, reduced maintenance costs, and long service life.

Oil-free Screw Air Compressors

Our oil-free screw air compressors provide 100% clean, contaminant-free air for critical applications in pharmaceutical, food & beverage, electronics, and healthcare industries. These systems ensure superior air quality while maintaining energy efficiency.

Why Choose IVITAL

At IVITAL, we combine industry expertise with customer-focused solutions to deliver exceptional air compression systems that meet your specific needs.

Quality Assurance

Rigorous factory selection and comprehensive testing protocols ensure every product meets our high standards.

Customization Services

Tailor-made solutions with customizable logos, specifications, and parameters to match your exact requirements.

Global Export Experience

Extensive experience exporting to North America, Europe, Middle East, Southeast Asia, and Africa with full compliance expertise.

Proven Success

Trusted by industry leaders across manufacturing, energy, healthcare, and food processing sectors worldwide.

Trusted by Global Brands

Customization Options

Tailor your air compression systems to your exact specifications with our comprehensive customization services.

Make your equipment truly yours with our professional logo customization services. We offer:

- Precision logo printing on equipment panels and casings

- Custom nameplate options with your brand identity

- Color-matched logo applications to maintain brand consistency

- Various size options to suit different equipment models

Our design team works closely with you to ensure your branding requirements are met with the highest quality standards.

Customize the performance parameters of your air compression system to match your specific operational requirements:

| Parameter | Available Options |

|---|---|

| Voltage | 110V, 220V, 380V, 400V, 415V, 480V |

| Pressure Range | 7-13 bar (100-190 PSI) |

| Flow Rate | 0.5-50 m³/min |

| Power Rating | 2.2kW to 250kW |

| Control Systems | Basic, Smart, Advanced, Industry 4.0 Compatible |

Our engineering team can develop custom solutions for special requirements beyond standard specifications.

Personalize the look and functionality of your equipment with our appearance and accessory customization options:

Color Options

- Standard colors: Blue, Gray, White

- Custom RAL color matching available

- Two-tone color schemes

- Special finishes (matte, glossy, textured)

Accessory Options

- Air treatment packages (filters, dryers)

- Extended connectivity modules

- Specialized mounting brackets

- Noise reduction packages

Special Requirements

We can accommodate special environmental requirements including weatherproofing, high-temperature operation, and corrosion-resistant coatings for harsh environments.

Ready to discuss your custom requirements?

Frequently Asked Questions

Find answers to common questions about our air compressors and services

Screw air compressors offer continuous airflow with lower noise levels and are ideal for constant operation in industrial settings. They have fewer vibrations and longer service intervals. Piston compressors, on the other hand, provide higher pressure capabilities but with more noise and vibration. They're typically more suitable for intermittent use and smaller applications where initial cost is a primary concern.

With proper maintenance, our industrial air compressors typically last 10-15 years. Screw compressors often have longer lifespans than piston models when used in similar conditions. Regular servicing, including oil changes, filter replacements, and component inspections, can significantly extend the operational life of your equipment. We provide detailed maintenance schedules with all our products to help maximize their service life.

Selecting the right screw air compressor depends on several factors: required air flow (CFM), pressure requirements (PSI/Bar), duty cycle, available power supply, and space constraints. You should also consider air quality requirements, energy efficiency, and future capacity needs. Our technical team can help analyze your specific application needs and recommend the most suitable model from our range of oil-lubricated or oil-free compressors.

Yes, IVITAL offers comprehensive OEM services. We can customize air compressors with your brand logo, packaging, and specific technical requirements. Our flexible manufacturing partnerships allow us to accommodate various customization needs, from simple branding to complete product specification adjustments. Minimum order quantities apply for OEM services, and our team will work closely with you throughout the development process.

We provide comprehensive after-sales support including: 1-2 year warranty on all products, technical assistance via email and video calls, detailed documentation and training materials, and a global network of service partners. For wholesale clients, we offer additional support with spare parts inventory management and technical training for your maintenance staff. Our commitment is to ensure minimal downtime and maximum productivity for your operations.

Still have questions? We're here to help.

Get in Touch

Interested in our air compressors? Fill out the form below to discuss your requirements.

Inquiry Form

Why Choose IVITAL?

Tell us your needs, and we'll get back to you within 24 hours with a tailored solution for your business.

-

Top-quality air compressors with customizable specifications

-

OEM services with your own branding options

-

Comprehensive after-sales support and warranty

-

Competitive wholesale pricing for distributors