Top-Quality Piston Air Compressors

Reliable | Customizable | Globally Available

About Piston Air Compressors

Piston air compressors are positive displacement compressors that use pistons driven by a crankshaft to deliver air at high pressure. They operate by drawing air into a cylinder, compressing it with a piston, and then discharging the compressed air into a storage tank.

Core Features

Durability

Built to last with robust components that withstand continuous operation in demanding environments.

Easy Maintenance

Simple design allows for straightforward maintenance procedures and accessible replacement parts.

Cost-Effective

Excellent value proposition with lower initial investment and long-term operational savings.

Applications

- Manufacturing Industries

- Pharmaceutical Production

- Automotive Repair

- Factory Operations

- Construction Sites

- Painting Applications

Product Range Overview

Explore our comprehensive range of air compressors designed for various industrial applications.

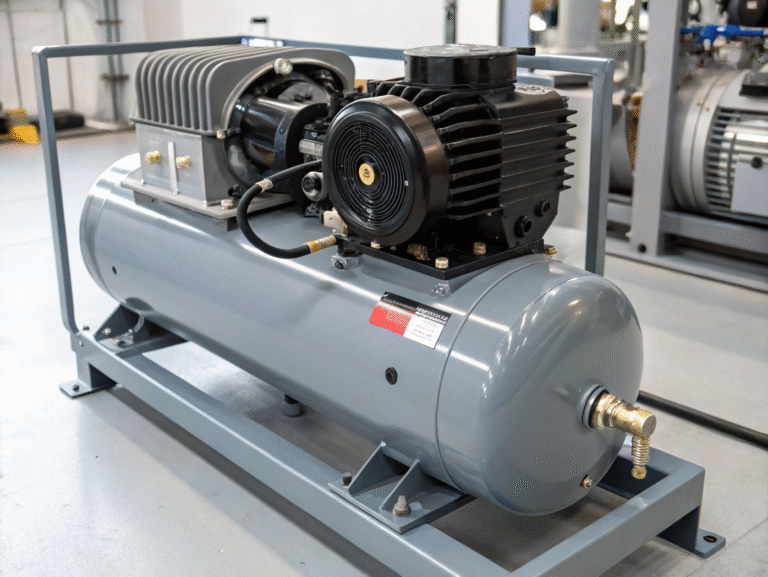

Single Stage Piston Compressor

Ideal for light-duty applications requiring moderate pressure. Perfect for small workshops, garages, and DIY projects where intermittent air supply is needed.

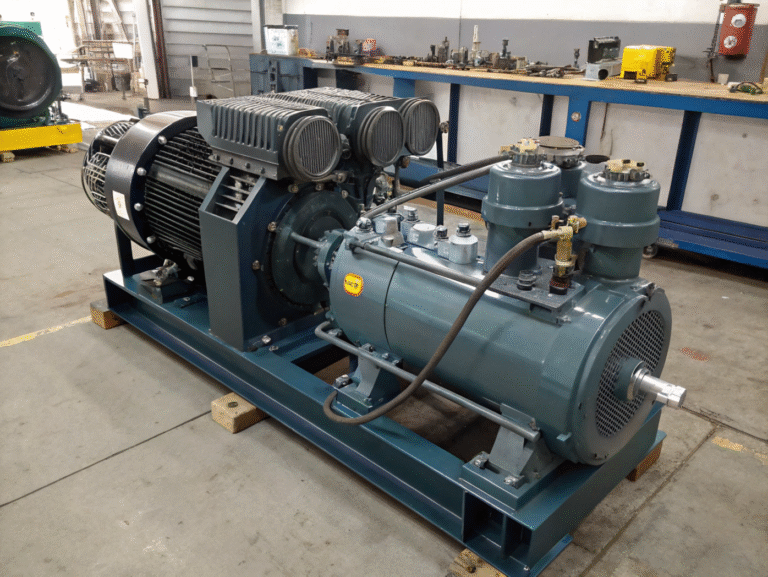

Two Stage Piston Compressor

Engineered for higher pressure requirements and continuous operation. Suitable for medium to large industrial facilities where consistent high-pressure air is essential.

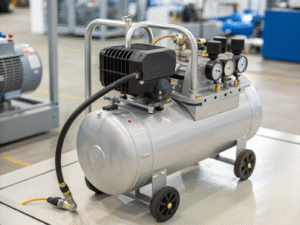

Oil-Lubricated Piston Compressor

Delivers superior durability and efficiency for heavy-duty applications. Ideal for manufacturing plants, auto repair shops, and other environments requiring reliable, long-term operation.

Oil-Free Piston Compressor

Provides clean, contaminant-free air essential for sensitive applications. Perfect for medical facilities, food processing, electronics manufacturing, and other industries requiring pure air quality.

Why Choose IVITAL

We deliver exceptional value and service that sets us apart in the industry

Factory Direct Pricing

Eliminate middlemen and enjoy competitive pricing through our direct factory supply model, ensuring maximum value for your investment.

Quality Certified

Our products meet rigorous international standards with ISO, CE, and other certifications, guaranteeing reliability and performance excellence.

Customization Services

Tailor products to your exact requirements with custom logos, specifications, and features designed to meet your unique business needs.

Global Export Expertise

Benefit from our extensive experience exporting to markets worldwide, with streamlined logistics and compliance knowledge for smooth international transactions.

Customization Options

Tailor our products to your exact specifications with our comprehensive customization services

Custom Logo

Add your brand identity with custom logo printing or embossing on products and packaging.

Color Options

Choose from our wide range of colors or specify your exact Pantone color requirements.

Accessory Modifications

Customize accessories and components to enhance functionality for your specific use case.

Special Purpose Modifications

Adapt products for specialized applications with engineering modifications to meet unique requirements.

Our Customization Process

-

Step 1

Submit Requirements

Share your customization needs and specifications with our team

1

-

2Step 2Engineering Assessment

Our engineers evaluate feasibility and develop a customization plan

-

Step 3Sample Confirmation

Review and approve prototype samples before full production

3

-

4Step 4Mass Production

Full-scale manufacturing of your custom products with quality control

-

1Step 1

Submit Requirements

Share your customization needs and specifications with our team

-

2Step 2Engineering Assessment

Our engineers evaluate feasibility and develop a customization plan

-

3Step 3Sample Confirmation

Review and approve prototype samples before full production

-

4Step 4Mass Production

Full-scale manufacturing of your custom products with quality control

Ready to create products tailored to your exact specifications?

Common Questions (FAQ)

Find answers to frequently asked questions about our air compressors and services

The average lifespan of our piston air compressors ranges from 10-15 years with proper maintenance. Industrial-grade models can last even longer, up to 20 years. Factors affecting longevity include operating conditions, maintenance frequency, duty cycle, and environmental factors. Regular oil changes, filter replacements, and inspection of key components can significantly extend the service life of your compressor.

Selecting the right compressor depends on several key factors: required air flow (CFM), pressure requirements (PSI), duty cycle (how often it will run), available power supply, and space constraints. Consider your specific application needs, such as whether you need continuous or intermittent operation. Our technical team can provide a detailed assessment based on your operational requirements to ensure you get the most efficient and cost-effective solution for your needs.

Regular maintenance is crucial for optimal performance and longevity. Here's a general maintenance schedule:

- Daily: Check oil levels and drain moisture from tanks

- Weekly: Inspect air filters and clean as needed

- Monthly: Check belt tension, inspect safety valves and pressure gauges

- Quarterly: Change oil (or every 500-1000 operating hours), replace air filters

- Annually: Comprehensive inspection of all components, including electrical systems and motor bearings

Always refer to your specific model's manual for detailed maintenance instructions or contact our service department for professional maintenance services.

Screw and piston compressors differ in several key aspects:

| Feature | Piston Compressors | Screw Compressors |

|---|---|---|

| Operation | Reciprocating motion | Rotary motion |

| Duty Cycle | Intermittent (50-60%) | Continuous (100%) |

| Noise Level | Higher | Lower |

| Initial Cost | Lower | Higher |

| Maintenance | More frequent | Less frequent |

| Efficiency | Lower at high volumes | Higher at high volumes |

Piston compressors are typically better for smaller applications with intermittent use, while screw compressors excel in continuous industrial applications requiring consistent air supply.

Our export packaging meets international shipping standards to ensure your equipment arrives safely:

- Standard Packaging: Heavy-duty wooden crates with reinforced corners, moisture-resistant barriers, and shock-absorbing materials

- Documentation: Complete with packing lists, certificates of origin, and product manuals in multiple languages

- Compliance: All packaging materials comply with ISPM-15 regulations for international shipping

- Container Loading: Optimized placement and securing methods to prevent movement during transit

- Customization: Special packaging requirements can be accommodated upon request

Each unit undergoes pre-shipment inspection and is properly secured to prevent damage during transportation across various shipping methods including sea, air, and land freight.

Still have questions? Our technical support team is ready to help.

What Our Clients Say

Discover why leading companies trust our services to deliver exceptional results.

Tech Solutions Inc.

Software Development

"The team delivered our project ahead of schedule and exceeded our expectations. Their attention to detail and technical expertise made a significant difference in our business operations."

Global Manufacturing Ltd.

Industrial Equipment

"We've partnered with this company for over five years now. Their consistent quality and reliability have helped us streamline our production processes and reduce operational costs by 30%."

Retail Innovations

E-commerce Solutions

"Their innovative approach transformed our online presence. Sales increased by 45% within the first quarter after implementation. The customer support team is always responsive and helpful."

Healthcare Partners

Medical Services

"Working with this team has been a game-changer for our patient management systems. The solutions they provided are HIPAA-compliant and have significantly improved our operational efficiency."

Financial Services Group

Banking & Finance

"Security and compliance are critical in our industry. Their team delivered a robust solution that meets all regulatory requirements while providing an intuitive user experience for our clients."

Logistics & Transport Co.

Supply Chain Management

"The tracking system they implemented has revolutionized our delivery operations. We've seen a 25% reduction in transit times and improved customer satisfaction scores across all regions."

Ready to Get Started?

Tell us your needs, and we'll offer the best solution tailored to your business requirements.

Your information is secure and will never be shared with third parties.

Typical response time: within 24 hours